Sorry for the slow progress with this one.... a bit of an educational update before we melt plastic!

Introduction to the main parts and the 3 axis

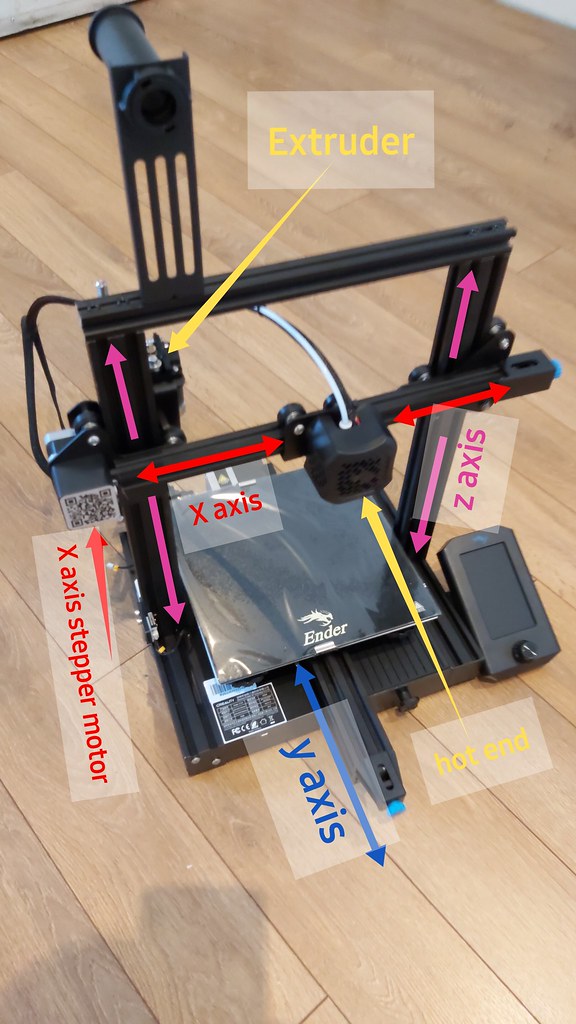

These are 3D, and the 3 axis are referred to as the X, Y & Z as shown below:

In this printer,

- The "X" axis is powered by a stepper motor pulling/pushing a toothed rubber belt which moves the "hot end" (the bit that prints) across that axis.

- The "Y" axis in my case is achieved by the glass bed sliding on its axis, again powered by a toothed belt and stepper motor.

- Finally, the "Z" axis is the up and down. Achieved on this printer by the rotation of a threaded bar that lifts and drops the horizontal gantry.

The filament pops onto that big handle up top (loosely) and you feed the end through the extruder. This is the device that pushes the filament (and pulls or retracts it) down the white tube and into the "hot end".

- Typical print temperatures are 200-220 degrees celcius

- Typical glass bed temperatures are 40-60 degrees celcius

I had it in my head that these print like a dot matrix ink-jet, only in 3 dimensions. Wrong. The extruder pushes out constantly and lays down small lines of plastic.

Here's the printer in action - its quite therapeutic to watch as it glides away!

So, how do you actually find stuff to print and how do you actually print it?

If like me you are a complete newbie to this, you'll have no hope (yet!) of designing your own stuff. I personally have ZERO experience of 3D CAD applications. Thankfully, there are many download sites where you can download your 3D print projects, already designed and ready to use.

Two main sites I've used are:

You can get lost in those 2 sites very easily! A world of stuff to download and print. If you are curious and on a Windows 10 PC, go ahead now and download some files. Windows has a 3D file viewer and you can open the shapes, zoom and look a little closer.

What file formats are these and do I need to buy software?

The 3D files are .STL files. These are 3D shapes/renders. You can open them in Windows 10 "3D Viewer" and your 3D printer will come with software to open it too. You can also download free slicing software here https://ultimaker.com/software/ultimaker-cura

You however can't get print these STL files. Your printer needs that 3D shape translated into actual instructions - layer by layer. This process is called "slicing" and you need software to open that STL 3D model and "slice it" into a .gcode file.

Don't freak out if you aren't overly technical.... let me recap...

- Download your chosen STL file and save to your PC/laptop

- Open that file in your slicer software

- Click "SLICE" and it'll save you a .gcode file

- Copy the .gcode file to microSD card and pop it in the printer

- You then print "standalone" as such... no PC involved to actually print.

That's a lot to take in... I'll take a break at this stage and fire away if there's any questions.

Next post... we'll start to print stuff!!

Reply With Quote

Reply With Quote