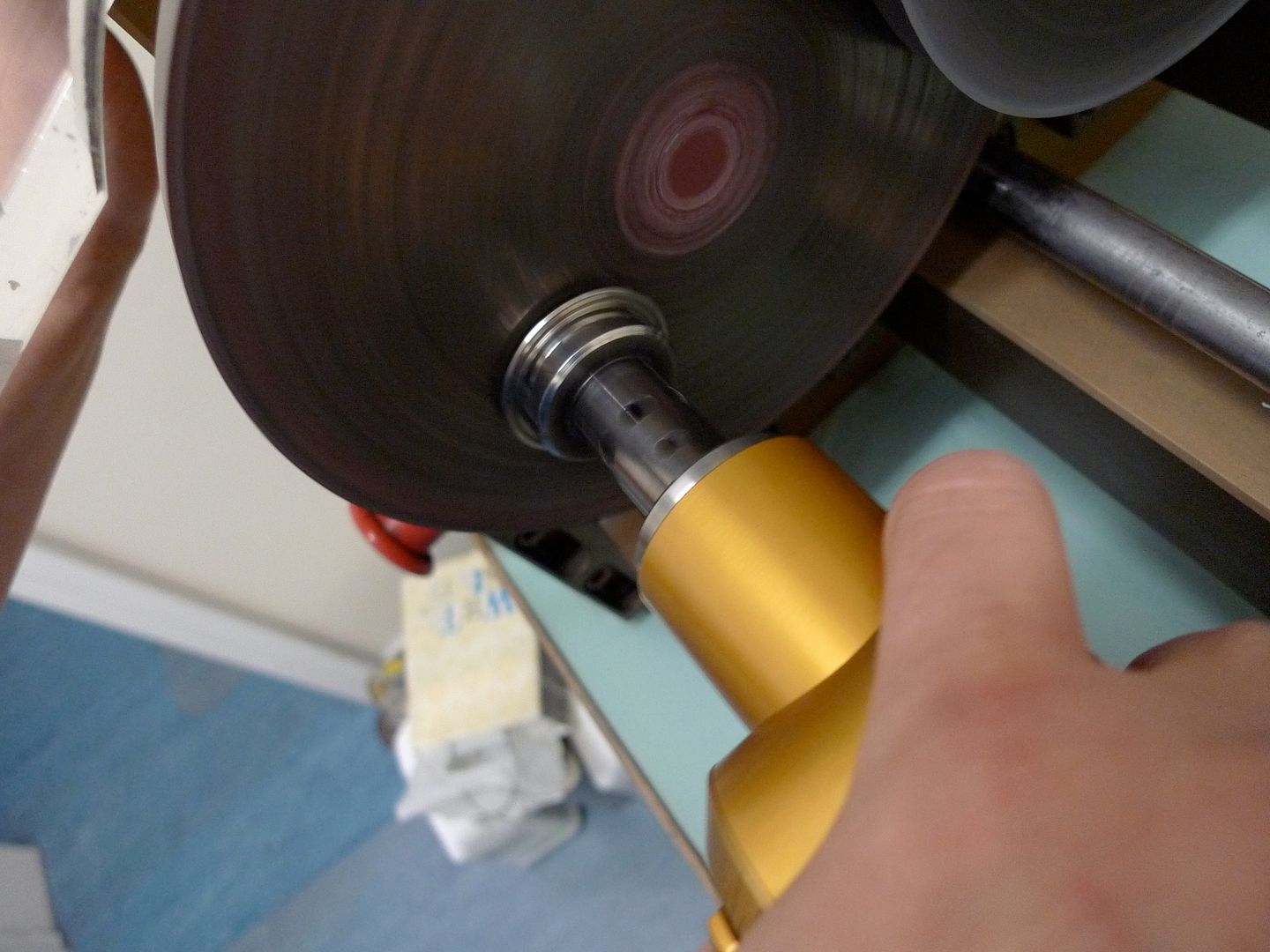

A quick pic of the results so far

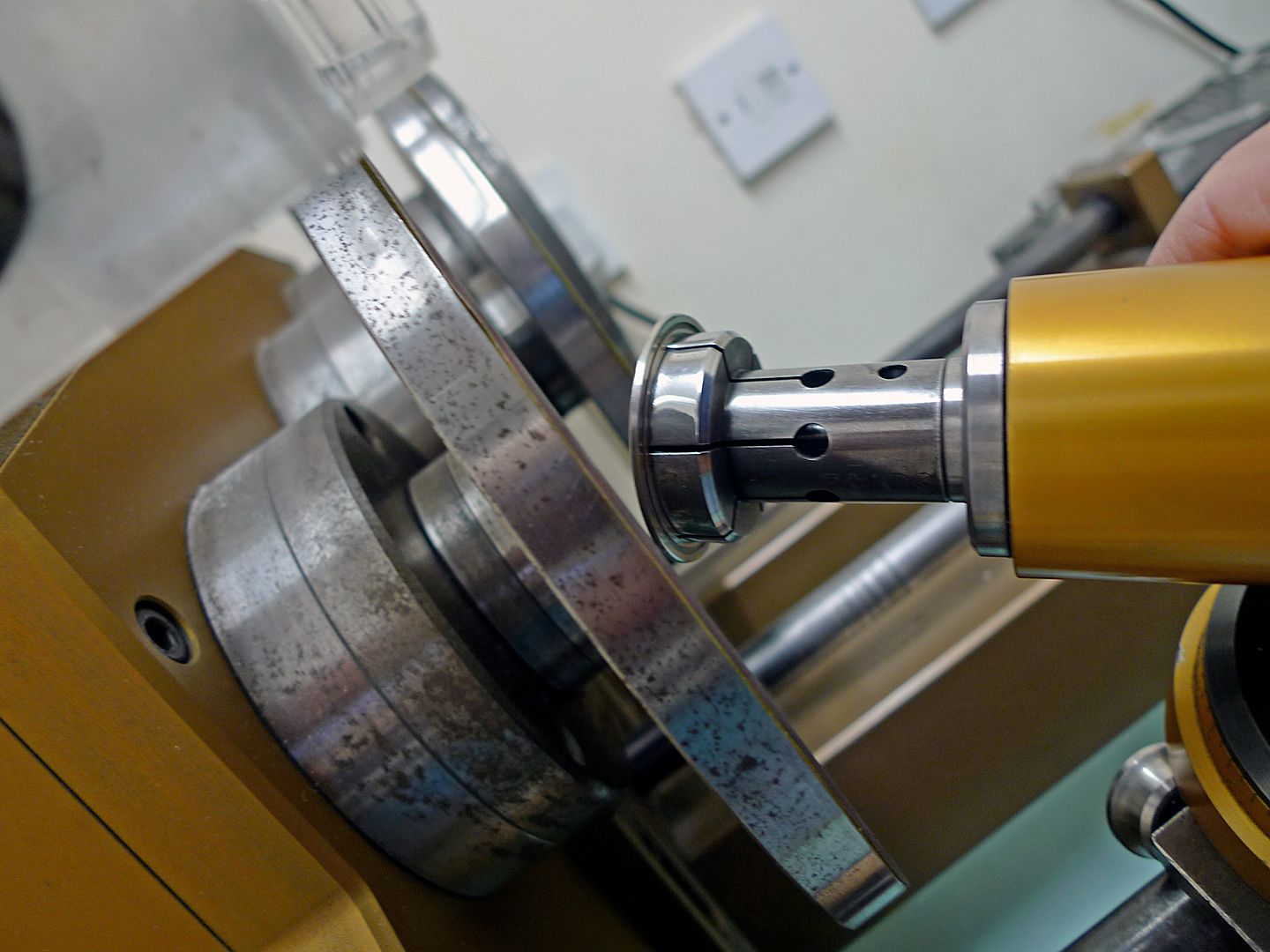

Next up it's time to refresh that faded paint. A fine screwdriver is used and capillary action draws the paint into the recesses.

Let the paint dry a little then wipe off any excess. Then bake until the paint is dry and hard.

And finally the end result

Some of the deeper dings are still evident. They could have been laser filled and then refinished but the customer didn't deem in necessary.

Hope that was interesting and any questions just yell.

Cheers,

Gary

P.S. A huge thank you to my local watchmaker for letting me be privy to this plus allowing me to take pictures and sharing them.

Reply With Quote

Reply With Quote