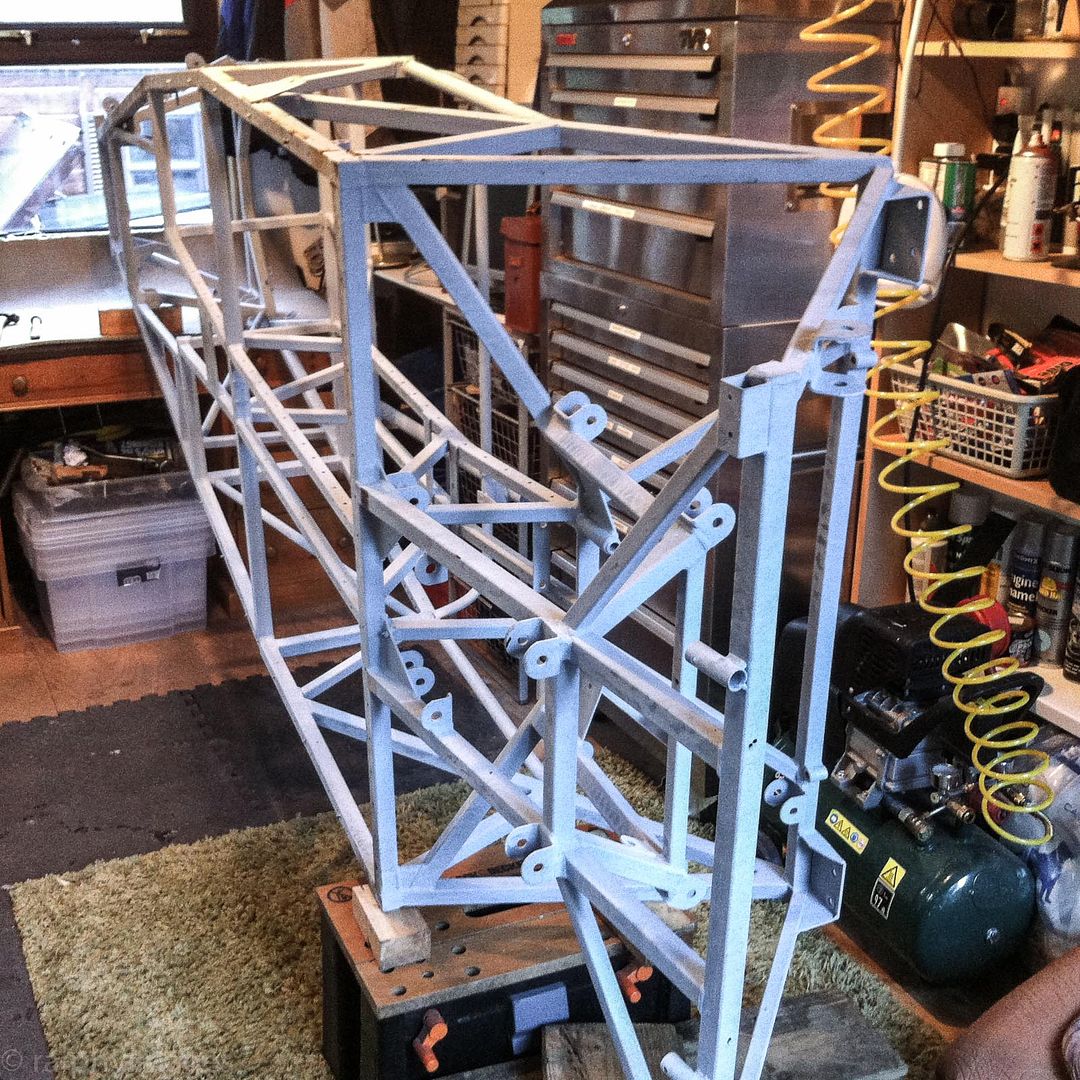

Today it actually stopped raining, so getting the chassis ready for the off to the blasters.

Joints: I wanted to give every one of welds a thorough inspection prior to be coated, so out with the wire brushes on them all

All looking pretty good and no evidence of structural degradation

Did I say there was a lot of them?

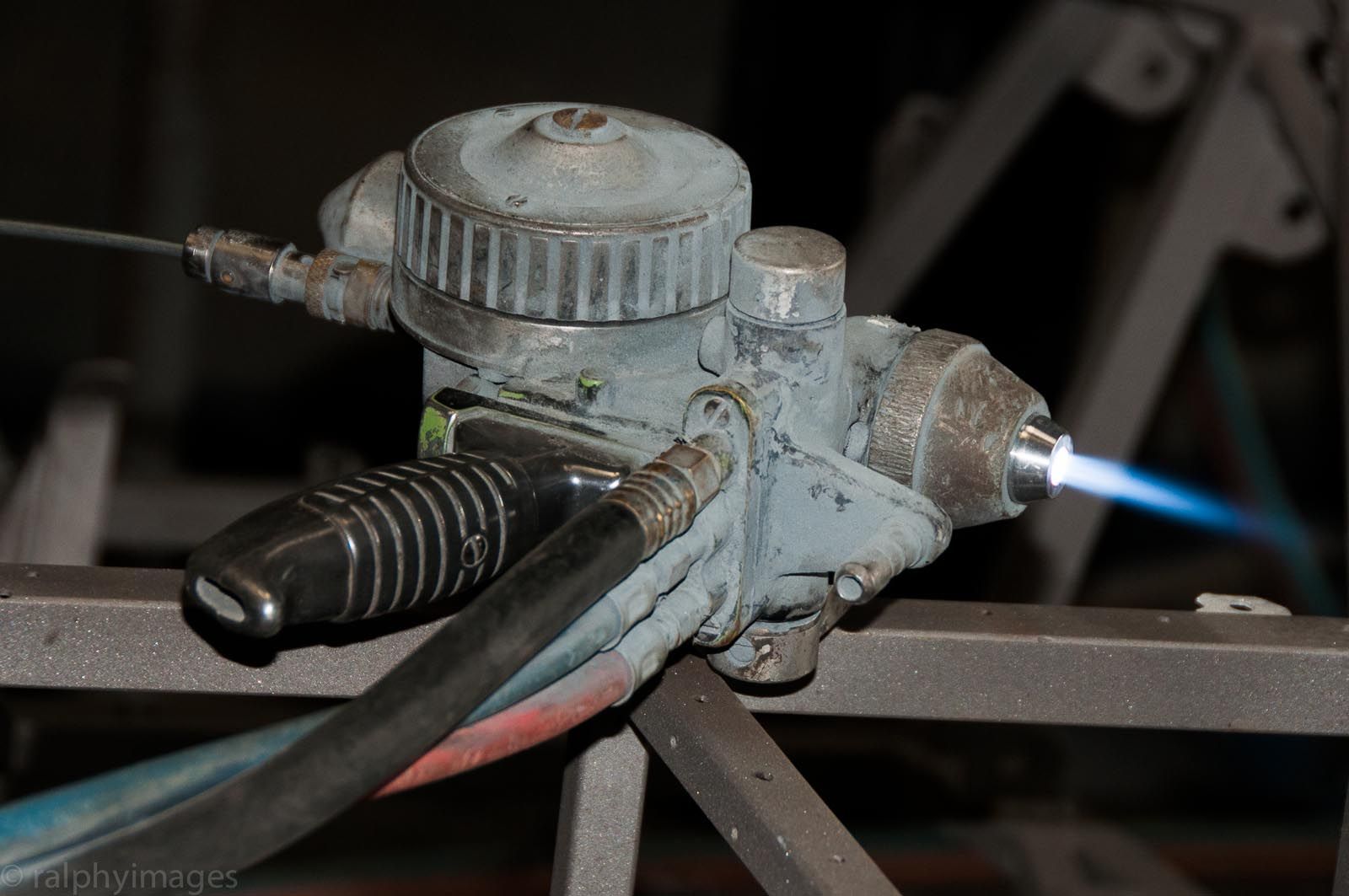

So onto the internals. The Westfield chassis is attached to the internal panels by rivets - loads of them. Now, I'm borderline phobic regarding hidden rust on vehicles so I was on full OCD agitation about water getting inside the tubular chassis via the rivet holes. A good look around inside with a boroscope was reassuring, but there was some slight surface coating so I wanted to stop any further deterioration and protect against any further ingress.

So it was time for the S-50 (I LOVE this stuff!)

The spray nozzle gives 360 degree coverage, so you simply push the tube in, start the pressure and steadily withdraw.

Finished the whole internals just in time to knock off for the day and within half an hour it started raining again!

R

Reply With Quote

Reply With Quote

F.T.F.A.

F.T.F.A.

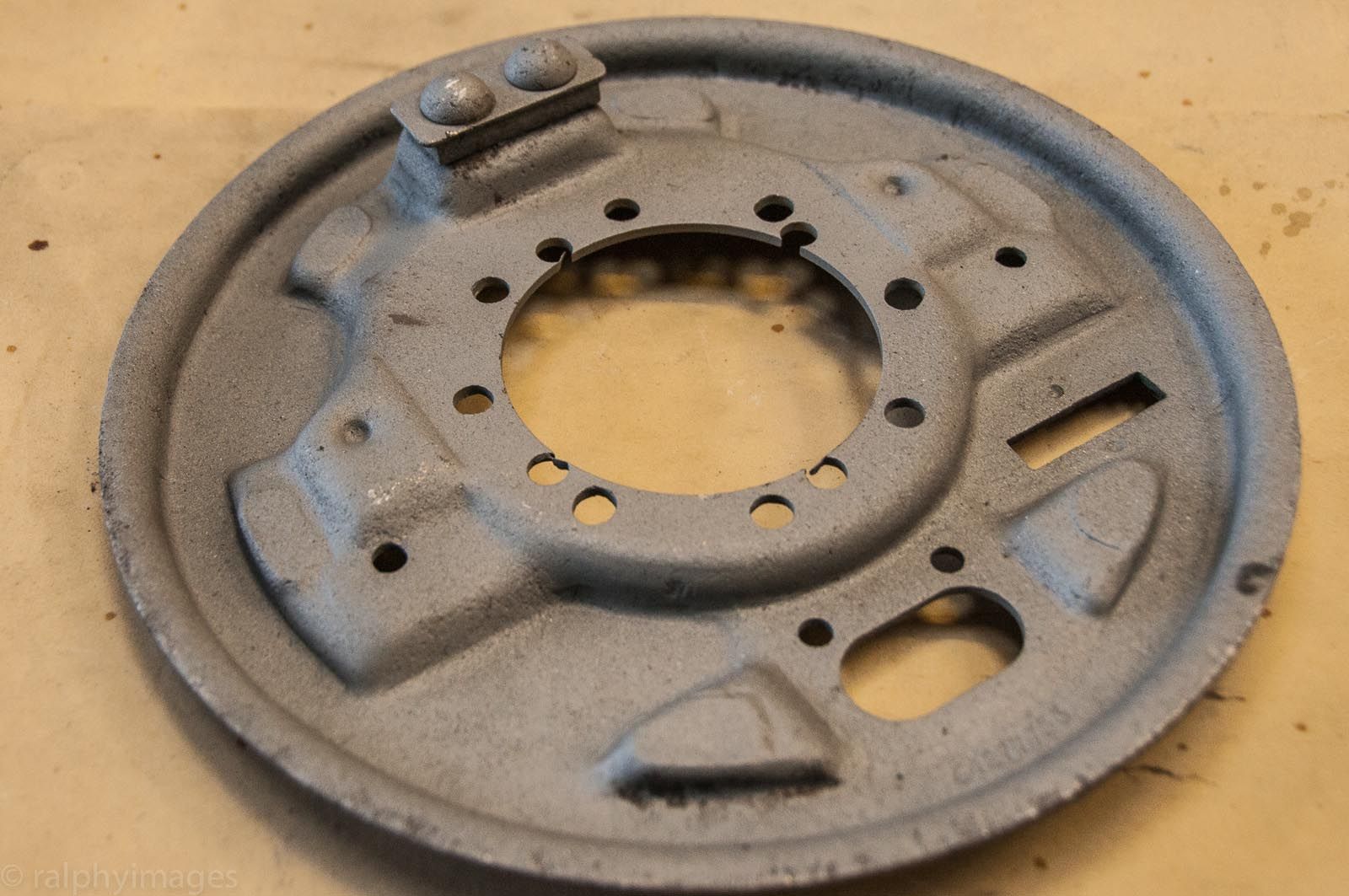

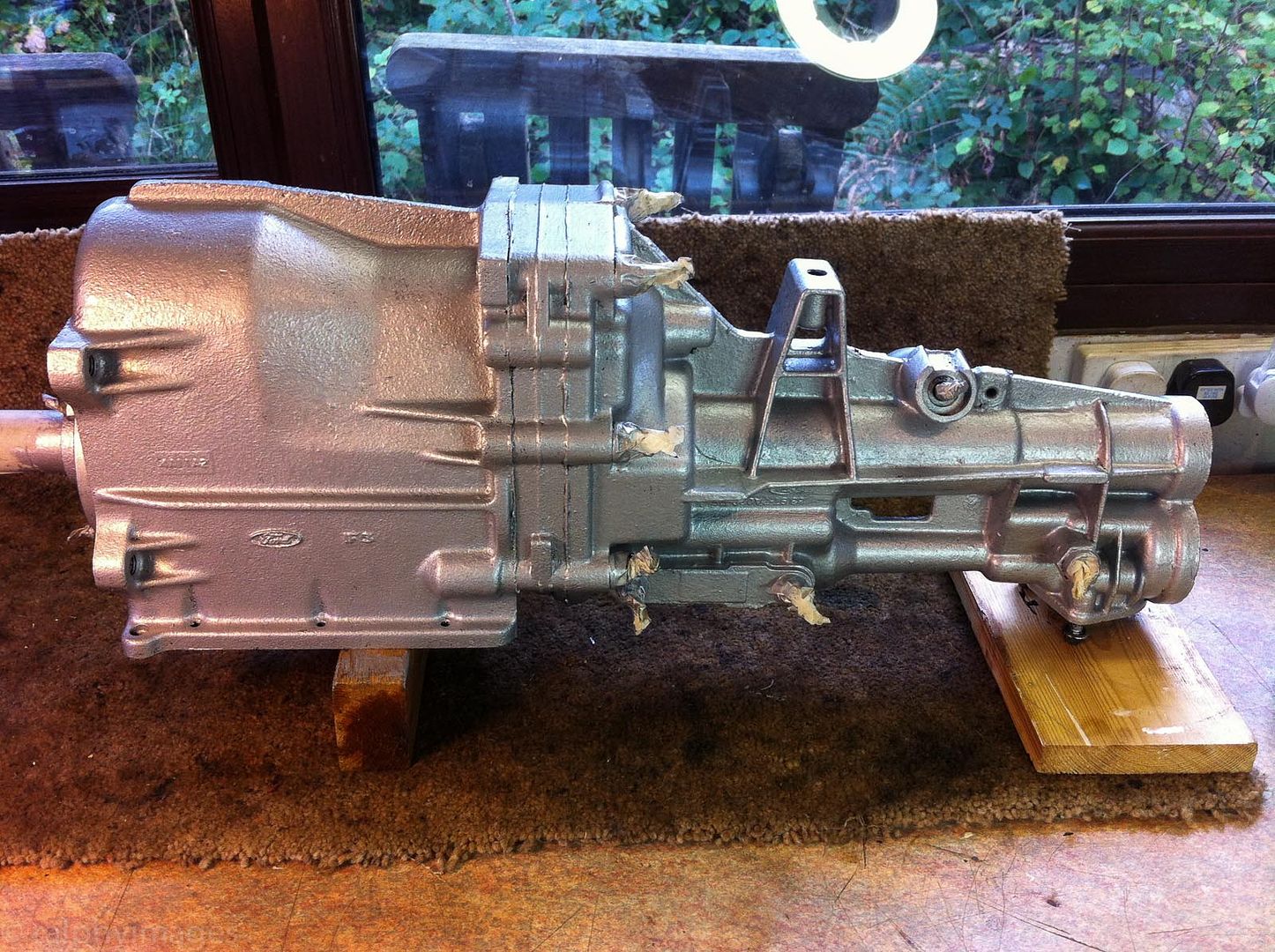

Successfully removed, back home and the hubs have been cleaned and painted up: they’re now in the ‘Done’ area for when reassembly starts. The half-shafts were now free for the same treatment:

Successfully removed, back home and the hubs have been cleaned and painted up: they’re now in the ‘Done’ area for when reassembly starts. The half-shafts were now free for the same treatment:

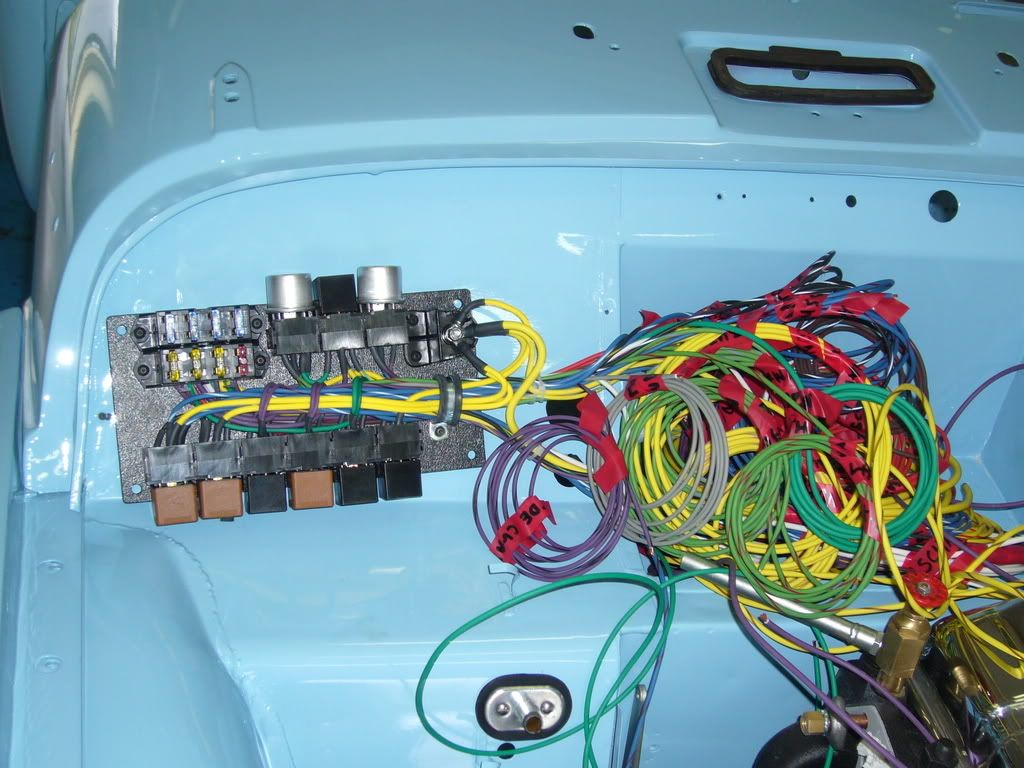

New loom then.

New loom then.