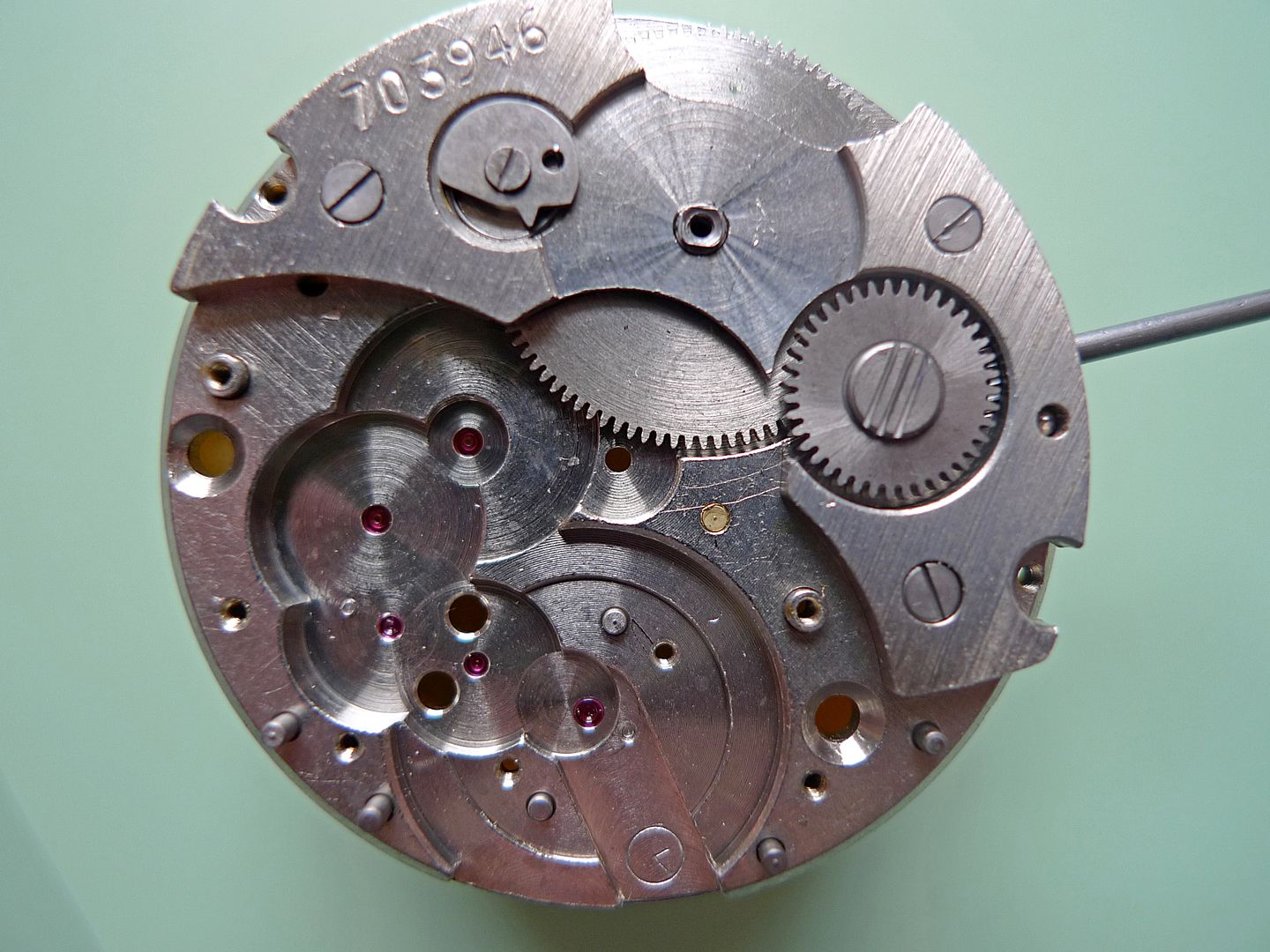

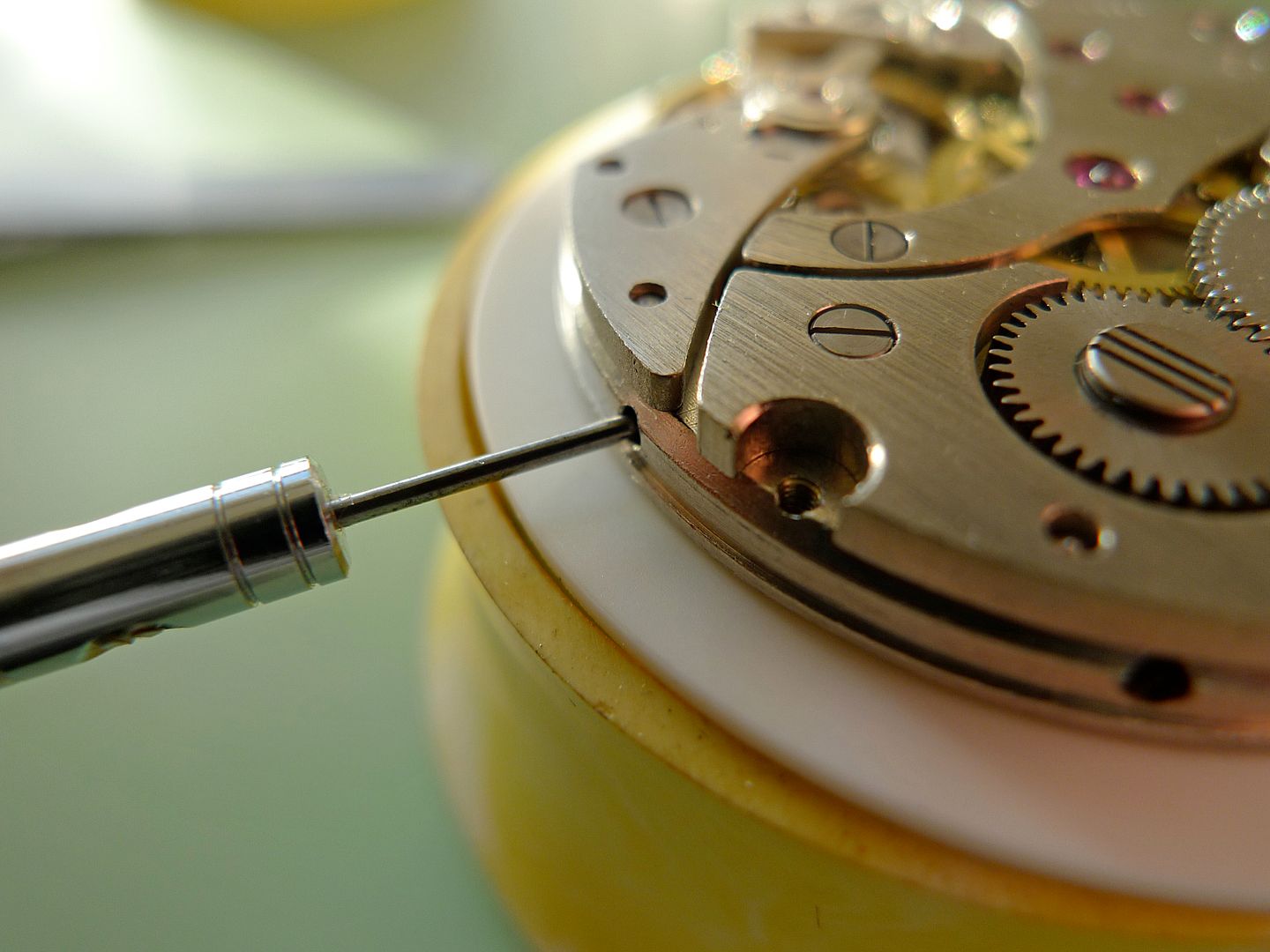

Next up is removing the movement from the case. It’s held in place by two screws which secure the movement to the inner rim of the case wall. They can be seen on the pic below. You’ll also notice that I’ve placed the watch dial down on a movement holder, this protects the dial and handset, never place a dial face down on a flat surface as you’ll invariably mark it.

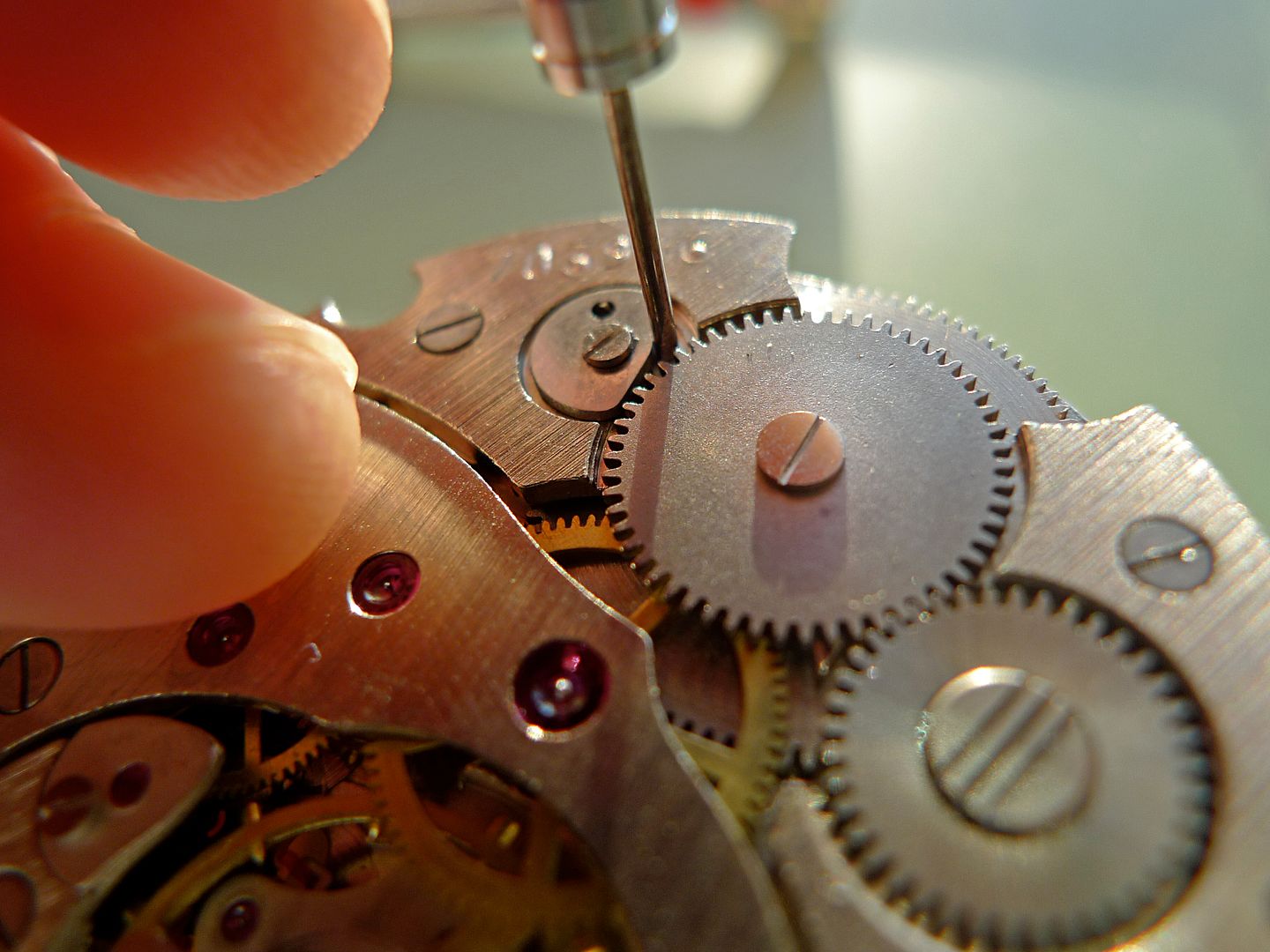

Remove the screws and use a screwdriver head that’s the same width or just marginally smaller than the slot in the screw. You don’t want to mark the screw heads at all.

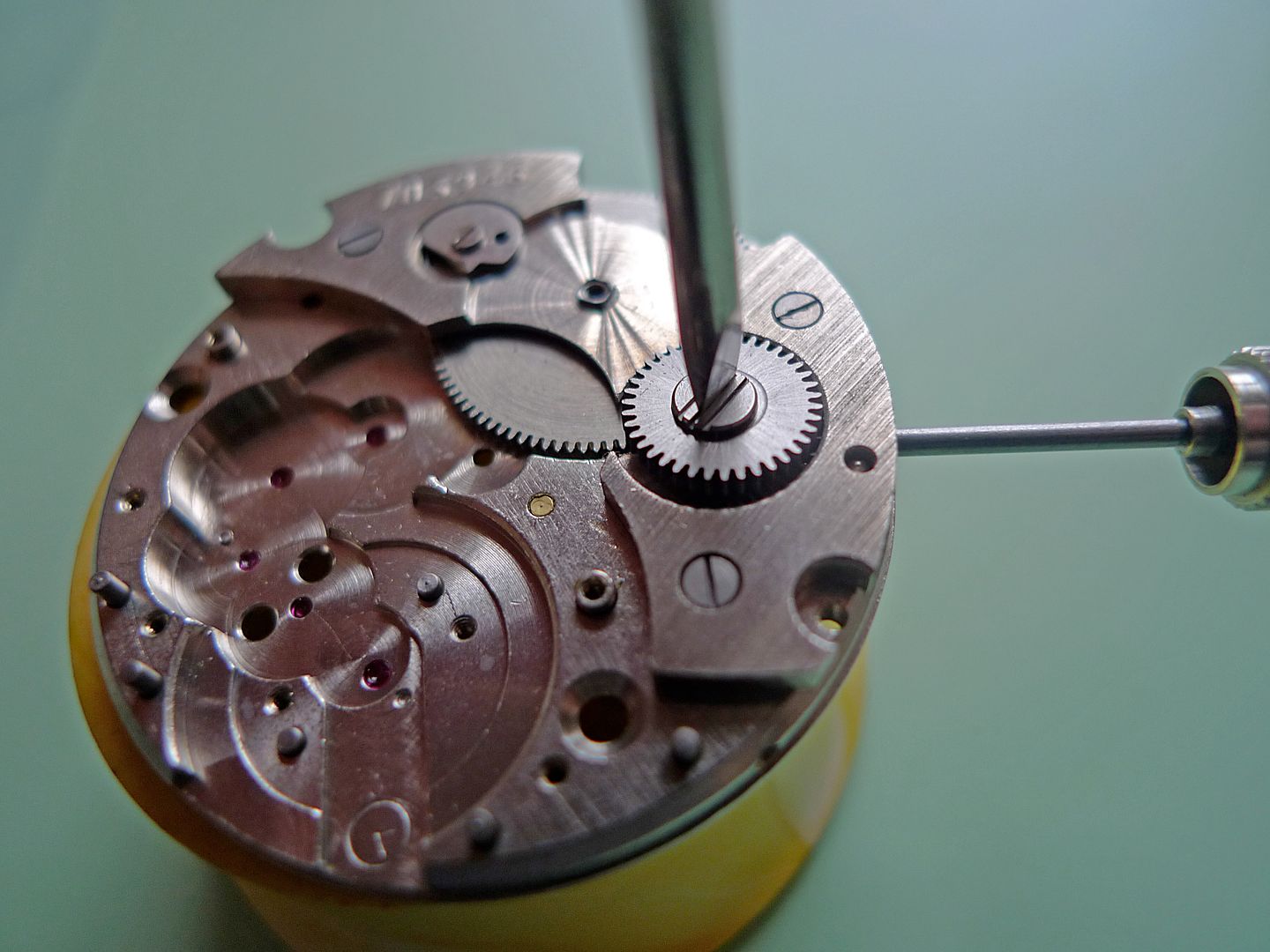

Both screws removed and stored safely the only thing that’s now keeping the movement in place is the stem. To remove this you press down the little button that’s near the stem entry point and pull the crown to release. This can be a little tricky and will feel fiddly at first but you soon get used to it. Some movements use a little screw which you loosen off a little to remove the stem which is a lot easier.

Stem removed you can now you can remove the inner section of the case.

To make handling the movement easier it’s then best to replace the stem. Most will just push back into place but some require you to press the stem release button to refit.

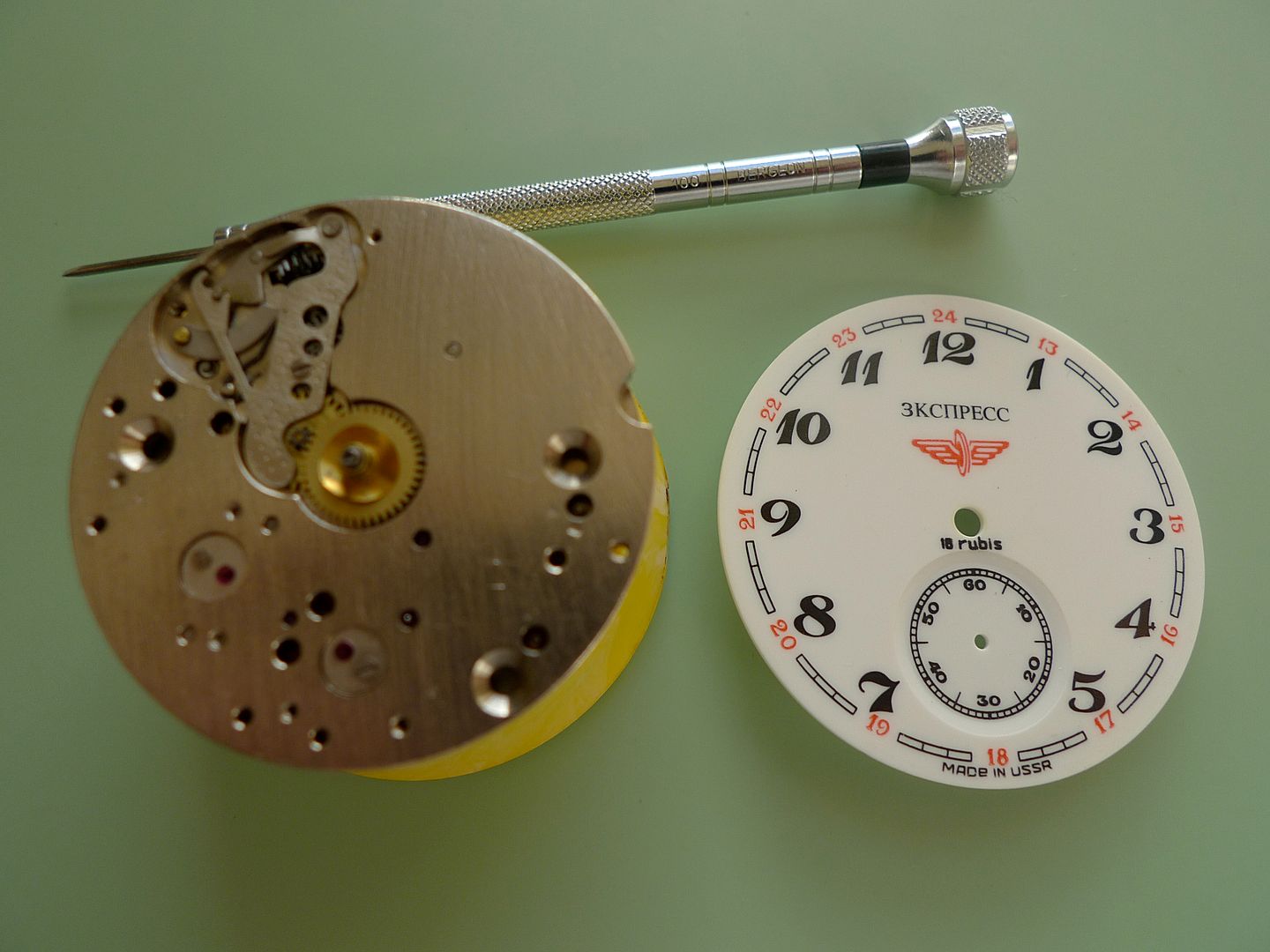

Then it’s time to remove the hands. I’m pretty old school so I use a traditional pair of hand levers to do this. First step is to put the watch on a stable base, then protect that dial, you don’t want to damage it or indeed touch it if you can help it. For this I use a sheet of plastic film, exactly like the film that watches and bracelets are protected by when they’re new. This not only protects the dial well but it has an added benefit, because it’s a little bit sticky it keeps the hands in place and prevents them from going flying. Not so important on a big watch like this but it can certainly save a lot of time searching for sub dial hands on a chronograph that have made their maiden voyage into thin air for example.

First set the hands to 12 o-clock, than place the film over the dial. Place the levers under the hour hand and gently lever upwards. They can be a pretty tight fit so don’t be afraid to apply a bit of pressure.

Then do the same with the seconds hand at 6, obviously you have to do this relatively quickly otherwise you might damage the hand.

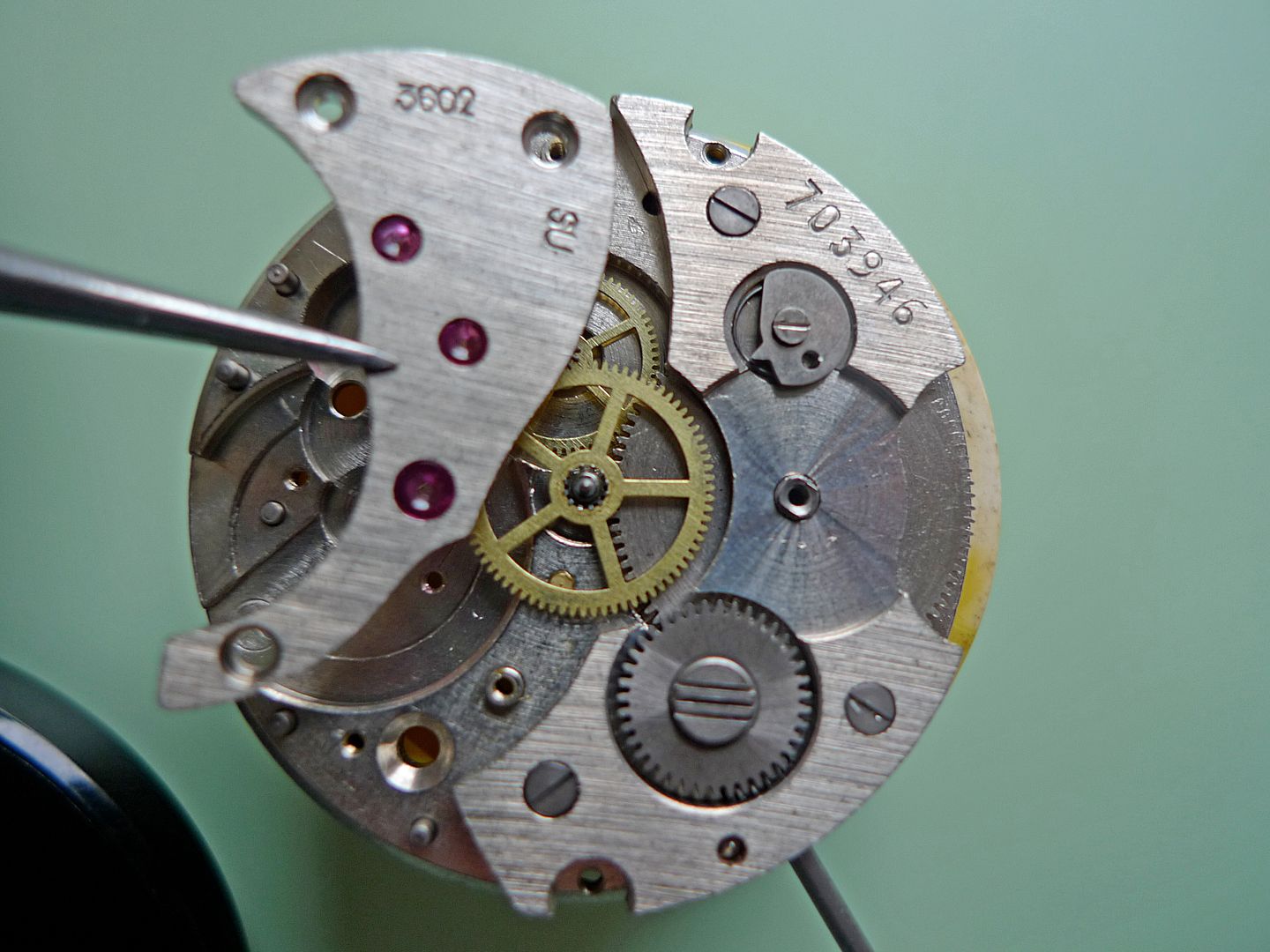

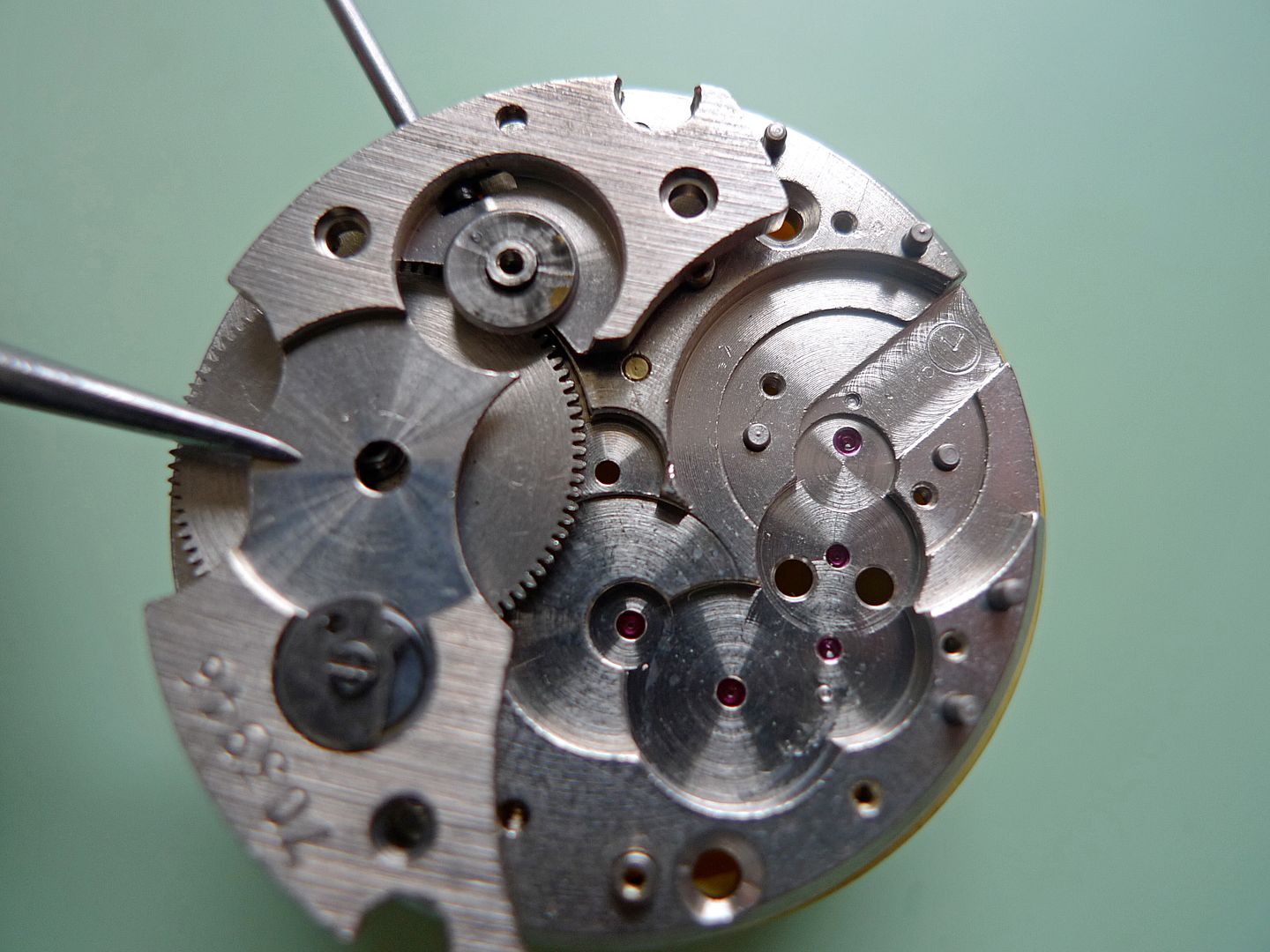

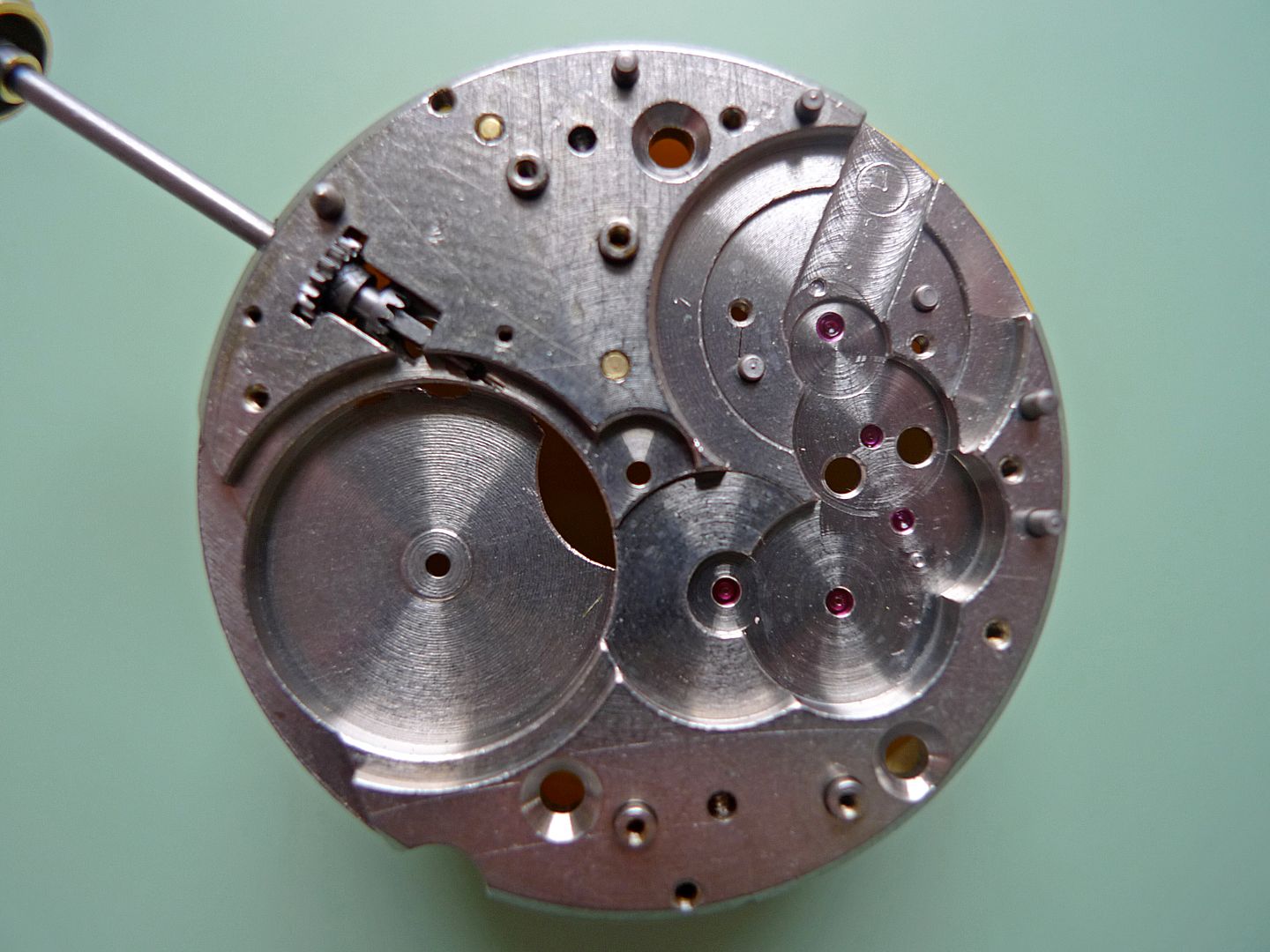

Hands off and stored safely it’s time to remove the dial. Most modern ETA movements have little hinged hooks that hold the movement in place, however older movements have screws on the side of the movement like this Molnija.

Loosen off both screws but don’t remove them completely.

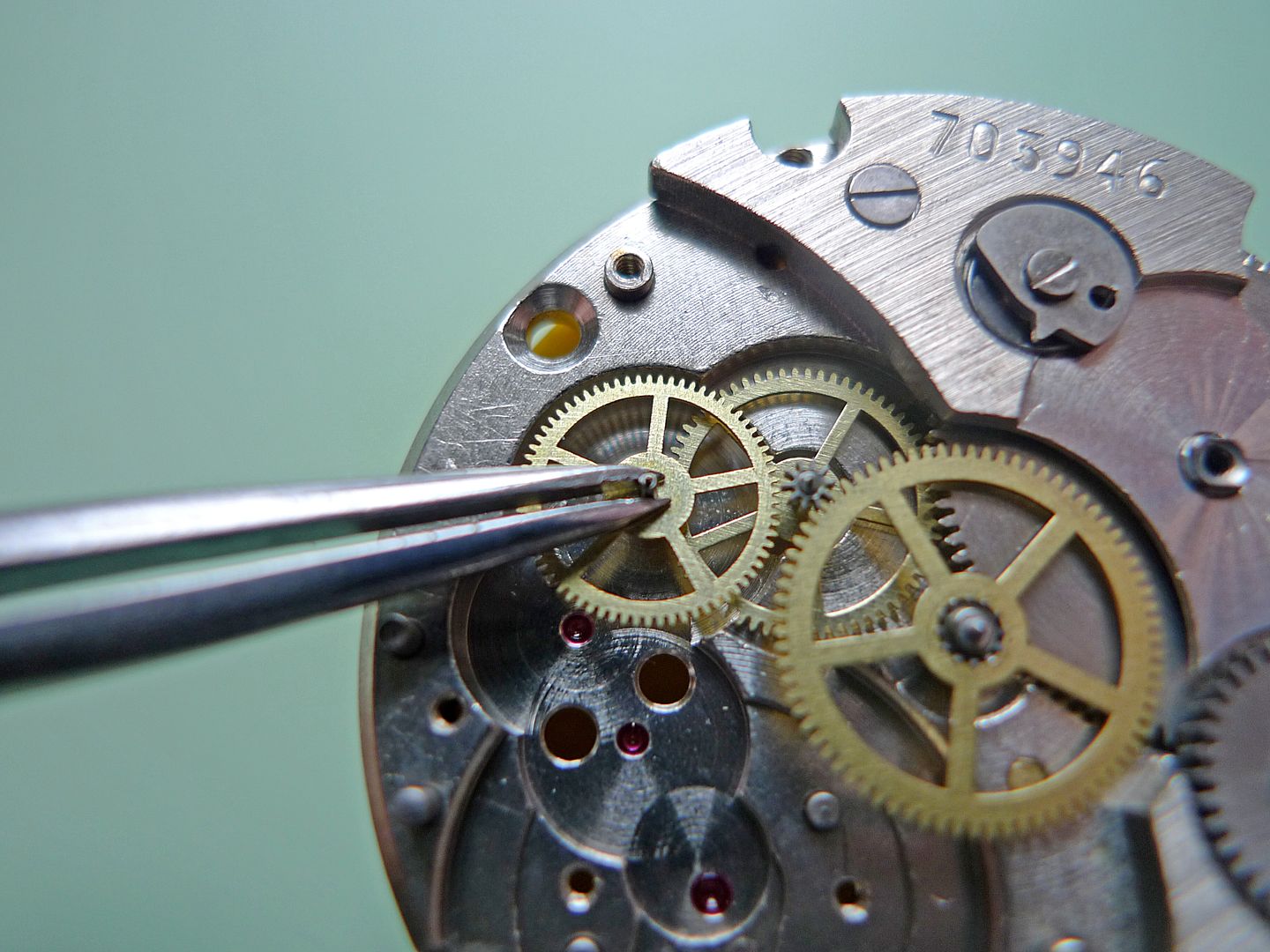

It might take a little bit of levering to remove the dial, my example was a pretty tight fit.

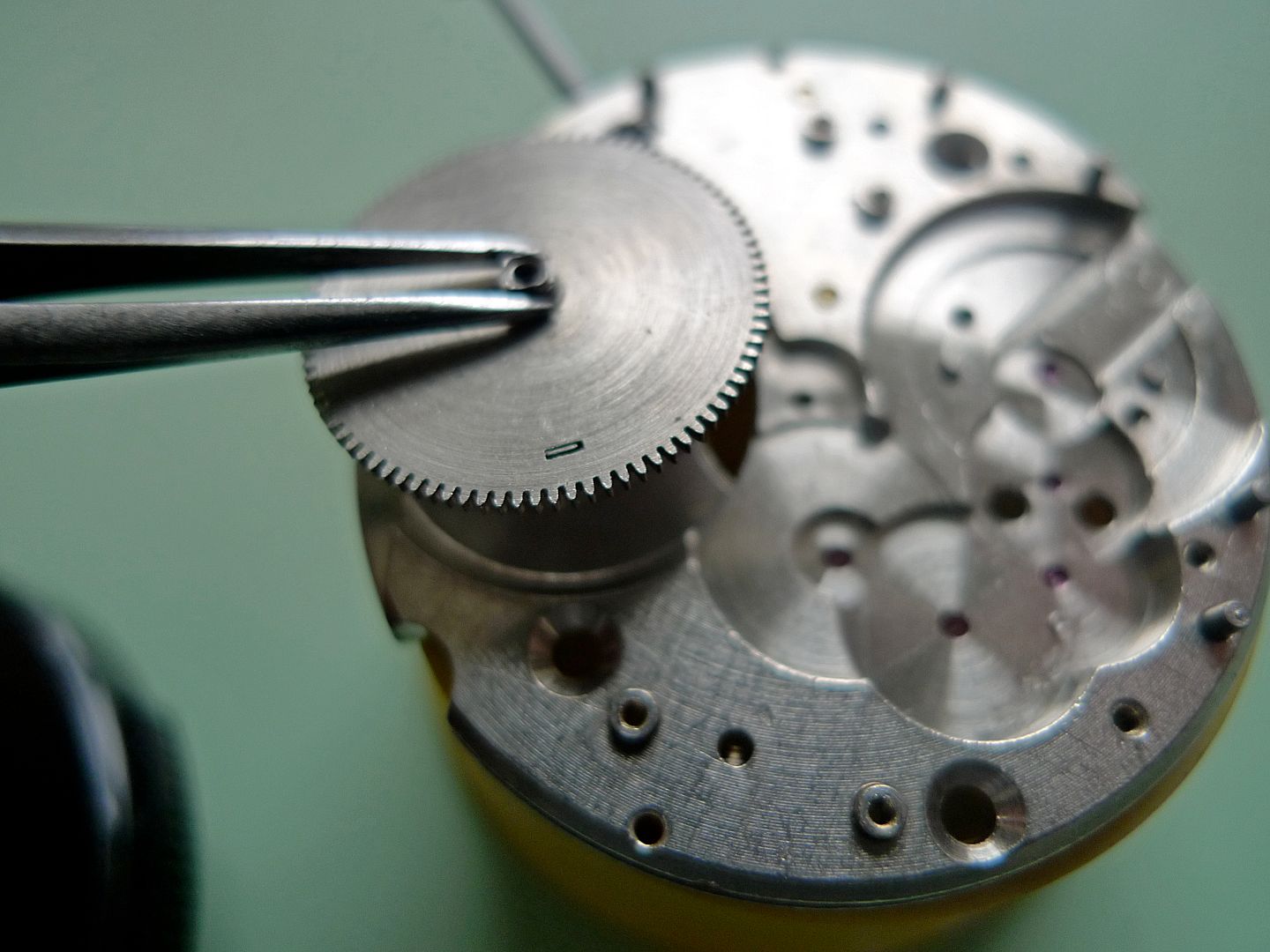

Here’s the reverse of the dial showing the two dial feet.

Once the dial is removed tighten the dial feet screws back up. If you don't and the movement goes into an ultrasonic cleaner they'll work loose and you'll lose them.

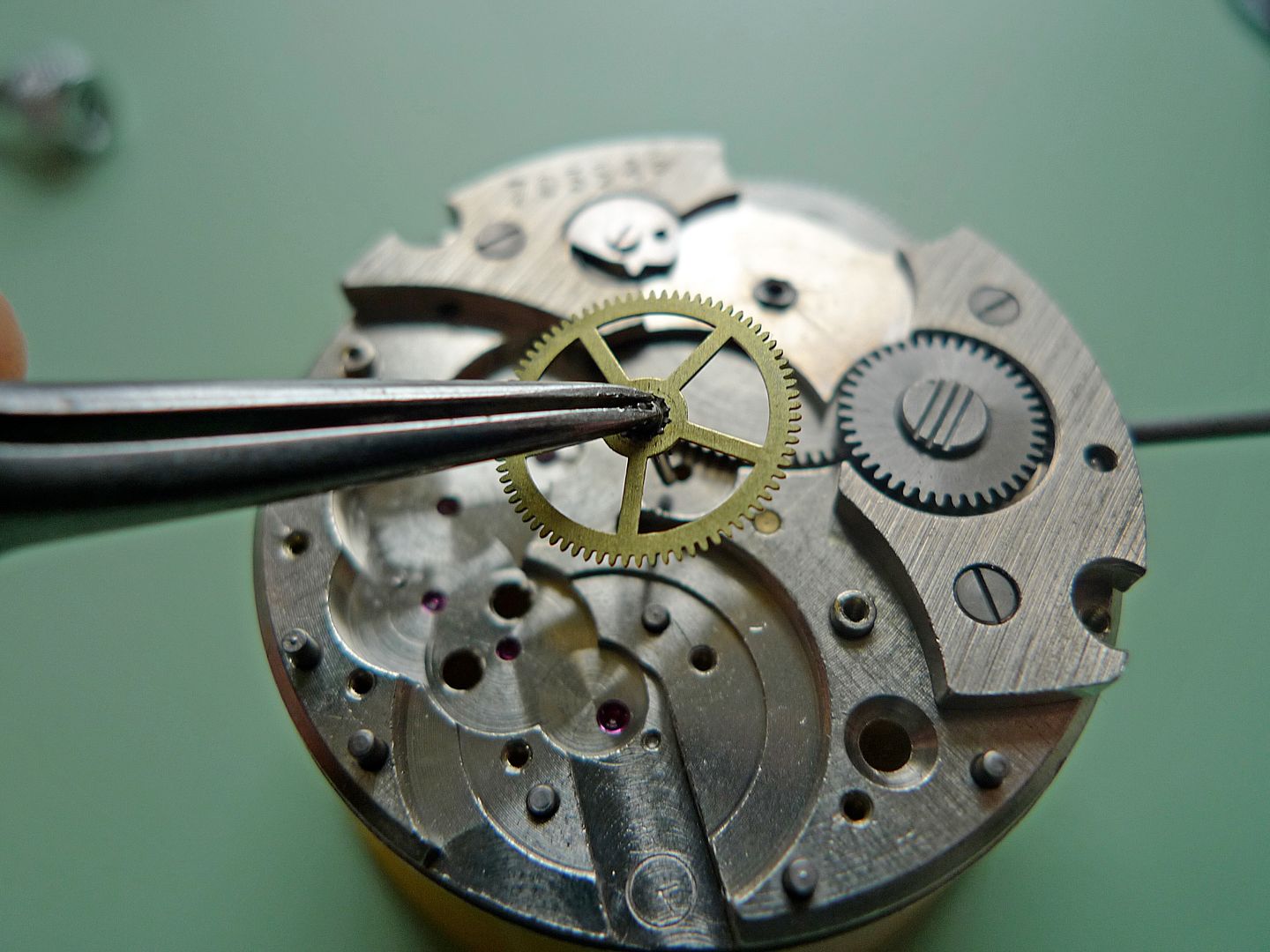

So now we have complete access to both sides of the movement. Hope it wasn’t too boring and it helped to illustrate the basics and how much goes into working with watches. If anyone’s interested in seeing dissembly of the movement I’ll add to this thread when I get the time and some light.

Thanks for reading.

Cheers,

Gary

Reply With Quote

Reply With Quote

)

)

F.T.F.A.

F.T.F.A.